GibbsCAM

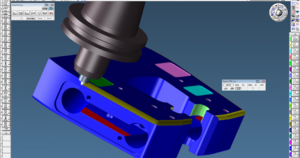

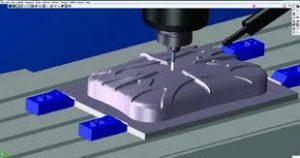

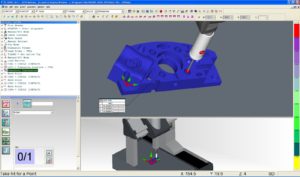

GibbsCAM is a state-of-the-art, PC-based computer-aided manufacturing (CAM) system for programming computer numerically controlled (CNC) machine tools.

GibbsCAM is organized as asingle application. The base package's capabilities can be optionally extended through the addition of seamlessly integrated modules. This way the system can be configured for your initial needs and be gradually expanded as your needs grow, protecting your investment.

GibbsCAM's graphical user interface was designed for machinists by machinists, resulting in a user environment that is both familiar and efficient. This manufacturing orientation ensures that GibbsCAM's powerful functionality is also extremely easy to learn and use.

GibbsCAM's free-form interaction style allows you to move easily between geometry creation, toolpath creation, process visualization/verification and post processing. GibbsCAM's ease-of-use, programming efficiency, speed and short training time makes GibbsCAM, the CAM industry's ease-of-use leader, the best tool for programming your parts.

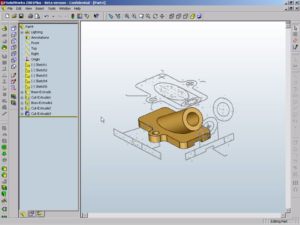

SolidWorks

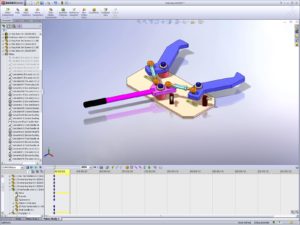

SolidWorks is a Parasolid-based solid modeler, and utilizes a parametric feature-based approach to create models and assemblies.

Parameters refer to constraints whose values determine the shape or geometry of the model or assembly. Parameters can be either numeric parameters, such as line lengths or circle diameters, or geometric parameters, such as tangent, parallel, concentric, horizontal or vertical, etc. Numeric parameters can be associated with each other through the use of relations, which allows them to capture design intent.

Design intent is how the creator of the part wants it to respond to changes and updates. For example, you would want the hole at the top of a beverage can to stay at the top surface, regardless of the height or size of the can. SolidWorks allows you to specify that the hole is a feature on the top surface, and will then honor your design intent no matter what the height you later gave to the can.

Features refer to the building blocks of the part. They are the shapes and operations that construct the part. Shape-based features typically begin with a 2D or 3D sketch of shapes such as bosses, holes, slots, etc. This shape is then extruded or cut to add or remove material from the part. Operation-based features are not sketch-based, and include features such as fillets, chamfers, shells, applying draft to the faces of a part, etc.

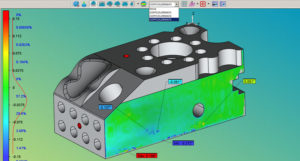

PC-DMIS CMM

PC-DMIS CMM is the world’s leading Coordinate Measurement Machine (CMM) Software with over 30,000 seats in place wordwide. Use its powerful capabilities to measure everything from simple prismatic parts to the most complex aerospace and automotive components.

PC-DMIS is standard equipment on all Hexagon Metrology CMMs including those under the brand names Brown and Sharpe, C.E. Johansson, DEA, Hexagon Metrology Asia Pacific, Leitz, Poli, Romer, Romer Cimcore, Sheffield and Tesa.

PC-DMIS CMM leads the way in revolutionizing CMM measurement. It wasthe first CMM software to:

- Use CAD models in the inspection process.

- Directly link CAD systems and measurement software though its Direct CAD interface (DCI) technology.

- Implement a full set of sheet metal measurement routines tailored for the automotive industry.

- Digitally simulate measurement in an offline virtual CMM environment.

- Easily align complex, contoured parts using our breakthrough iterative alignment technology.

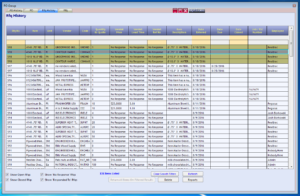

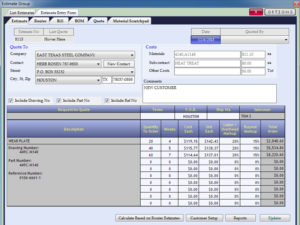

Shop floor control... Realtrac job shop software is your window to the shop floor, where you have up-to-the-second visibility of machines, employees and jobs. You can respond to customer job status inquiries NOW- where it is, and when it will be finished. As conditions change, the system is updated immediately, even as you watch it on your screen.

Scheduling and Estimating... allows you to do graphic analysis of "what if " simulations, changing priority assignments and loading schedules. Scheduling can be backward or forward. Jobs may be scheduled independently, linked to assemblies, or predetermined lot releases - all handled in real-time. Estimates show multiple quantity delivery times based on current work center loads.

Materials Management System... simplifies the preparation and tracking of material and outside service purchase orders. A complete inventory control system for raw material, finished and semi-finished parts, customer supplied material and tooling has been designed especially for use by job shops.

Job Costs and Management Analysis... with instant Work-In-Process reports. You have a complete up-to-the-minute history, not only for current jobs but past jobs as well, allowing you to evaluate performance, prices and delivery promptness. You can determine profitability by customer, by machine or by employee, and make rational decisions based on solid information as of right now.

Integrates with QuickBooks®... Posting of Realtrac invoices updates customer balances and general ledger accounts, while posted purchase orders allow for easy entry and payment of vendor charges. Realtrac employee time summary reports simplify the preparation of payroll checks.

Multimedia Shop Floor Documentation... further enhances ISO 9002 tracking by the use of digital camera pictures, drawings, sketches, and sound. CAD drawings, SPC control graphs, and hand sketches can be transferred directly into Realtrac's multimedia library and then viewed, printed and linked directly to router operations.

Bar Code Data Collection... uses low-cost shop floor bar code microterminals or PC's to record events as they occur. Shop floor personnel communicate with the system in a two-way, error checking dialog, which provides job start and finish times, piece and scrap counts, and non-production factors such as down-time for machine maintenance - the information you need to keep current on shop floor status.